|

| Home |  | Aalborg- Model T single flow tube PTFE meters | |

|

|

|

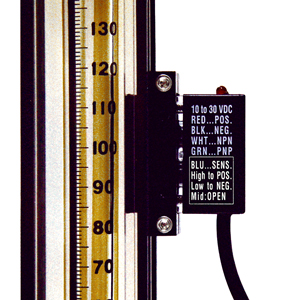

model T single flow tube PTFE meters

model T single tube PTFE/Glass flow meter for low flow rate measurement

Design Features

- constructed of inert materials:

-

chemically inert wetted parts

-

rib-guided or fluted metering tubes facilitate stable/accurate readings

-

magnifier lens in front shield to enhance reading resolution

-

OPTIGRAD™ scales minimize parallax and eye fatigue

-

simple means of panel mounting

-

interchangeability of flowtubes and floats

-

conveniently overlapping flow ranges available in both standard millimeter and direct reading scales.

Designed for low flowrates, the model T flowmeter is a precision

instrument embodying the inherent simplicity, versatility and economy of

the classical variable area meter. It is particularly suitable for

metering carrier gases in chromatography, indicating and controlling

gases in manufacturing processes, liquid and gas measurement in

laboratories, pilot plants, flow and level indicating, etc. 150 mm Meter

with CV™ Valve. Shipped completely

assembled, flowmeters include standard mounting fittings in a choice of

materials, side plates, thick protective magnifying front shield and

back plate, optional built-in control valve, and flowtubes selected from

the Flow Capacities tables. Panel mounting style is convertible to

bench mounting through the use of the optional acrylic tripod. The

tripod has a built-in spirit leveler and leveling screws.

Flow tubes for these meters are available with two types of scales, suitable for different types of applications

DIRECT READING SCALES

Direct

reading scales are indicating flow rates of liquids and gases,in

engineering units such as [mL/min], standard cubic feet per hour [scfh]

etc. Such scales are designed exclusively for a specific gas or liquid

at a given set of pressure and temperature parameters, and are valid for

the associated units of flow only. The convenience of direct reading

scale designs should be weighed against the resultant limitations of

applicability. Generally, direct reading scales are most suited to OEM

applications.

UNIVERSAL MILLIMETER (CORRELATED) SCALES

Millimeter

scales indicate the vertical position of the spherical float within the

metering tube as the flow increases or decreases.

It is necessary to use flow tables or graphs supplied, to correlate float referenced readings with actual volumetric flow rates.

The

advantage of Universal type scales is the ability to utilize the use of

a given flow meter for a great number of different fluids at diverse

pressure and temperature conditions, generally preferred in applications

in laboratories, etc.

Meters

are available with built-in needle valves (CVT™ ), high precision

metering valves (HRT™) with “non-rising stems”, or with no valves. The

higher cost of HRT™ valves is justified whenever high sensitivity

control and resolution are desirable particularly in conjunction with

metering tubes of very low flowrates.

When meters with valves are

ordered the valve cartridges are installed at the inlet. For vacuum

service it is recommended that meters are ordered with valves at the

outlet.

| SPECIFICATIONS |

|

STANDARD ACCURACY ±2% FS (mm scales - except 032/042 flow tubes); ±5% FS (direct reading scales and 032/042 flow tubes) |

| CALIBRATED ACCURACY ±1% FS |

| REPEATABILITY ±0.25% FS |

| USEFUL FLOW RANGE 10:1 minimum with one float |

| MAXIMUM OPERATING PRESSURE 100 psig (6.7 bars) |

| MAXIMUM OPERATING TEMPERATURE 150°F (65°C) |

|

LEAK INTEGRITY individually pressure and leak tested and certified to a rating of 1x10-7 sccs helium

|

| MATERIALS OF CONSTRUCTION |

|

FLOW TUBES heavy walled borosilicate glass (glass or sapphire floats recommended) |

| FITTINGS IN CONTACT WITH FLUIDS virgin PTFE and PCTFE |

| SIDE PANELS aluminum, black anodized |

| FRONT SHIELD Lexan® with longitudinal magnifier lens for enhanced reading resolution |

| BACK PLATE 1/8 inch thick white acrylics |

| O-RINGS PTFE |

|

|

|

|

|

|

|

|

Ancor Sdn Bhd

D-2-4, Setiawalk, Pusat Bandar Puchong, 47160 Puchong, Selangor, Malaysia

Tel: +6012-921 3877 , 03-58797121

Email: info@ancor.com.my ; ancor.my@gmail.com

|

|

|

|

|